‘Supercritical coal-fired power plant’ – Necessary to promote

advanced technology in power generation for achieving better

efficiency, cleaner and safer environment:

Introduction –

Energy, in general, and electricity in particular, plays a vital role

in improving the standard of life everywhere. World has abundant proven

reserves of coal and thus coal-based thermal power plants dominate

almost everywhere. The development of coal fired supercritical power

plant technology can be described as an evolutionary advancement towards

greater power output per unit and higher efficiency. Energy conversion

efficiency of steam turbine cycle can be improved by increasing the main

steam pressure and temperature.

As name suggests, coal-fired

supercritical power plants operate at very high temperature and pressure

(580 degree centigrade temp. with a pressure of 23 MPa) resulting much

higher heat efficiencies (46%), as compare to sub-critical coal-fired

plants which operates at 455 degree centigrade temp., and efficiency of

within 40%. Some of the benefits of advanced supercritical power plants

include:

(a) Reduced fuel costs due to improved plant efficiency;

(b) Significant improvement of environment by reduction in CO2 emissions;

(c) Plant costs comparable with sub-critical technology and less than other clean coal technologies;

(d) Much reduced NOx, SOx and particulate emissions;

(e) Can be fully integrated with appropriate CO2 capture technology.

Supercritical technology and its advantages -

In other words, supercritical power plants are highly efficient plants

with best available pollution control technology, reduces existing

pollution levels by burning less coal per megawatt-hour produced,

capturing the vast majority of the pollutants. This increases the kWh

produced per kg of coal burned, with fewer emissions.

Because of

the above techno-economic benefits along with its environment-friendly

cleaner technology; more and new power plants are coming-up with this

state-of-the-art technology. As environment legislations are becoming

more stringent, adopting this cleaner technology have benefited

immensely in all respect. As LHV (lower heating value) is improved (from

40% to more than 45%); a one percent increase in efficiency reduces by

two percent, specific emissions such as CO2, NOx, SOx and particulate

matters.

Increased thermal efficiency

observed when the temperature and pressure of the steam is increased. By

raising the temperature from 580 °C to 760 °C and the pressure out of

the high pressure feed-water pump from 33 MPa to 42 MPa, the thermal

efficiency improves by about 4% (Ultra-supercritical steam condition).

Moreover,

there are various operational advantages in case of supercritical power

plant. There are several turbine designs available for use in

supercritical power plants. These designs need not fundamentally differ

from designs used in sub-critical power plants. However, due to the fact

that the steam pressure and temperature are more elevated in

supercritical plants, the wall-thickness and the materials selected for

the high-pressure turbine section need reconsideration. The

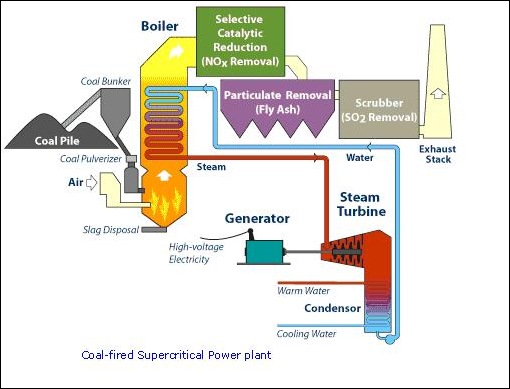

supercritical plant needs ‘once-through’ boiler, where as ‘drum’

type boiler is required by sub-critical power plant. In fact,

once-through boilers are better suited to frequent load variations than

drum type boilers, since the drum is a component with a high wall

thickness, requiring controlled heating.

The performance of

supercritical plant depends on steam condition. Steam conditions up to

30 MPa/600°C/620°C are achieved using steels with 12 % chromium content.

Up to 31.5 MPa/620°C/620°C is achieved using Austenite, which is a

proven, but expensive, material. Nickel-based alloys, would permit 35

MPa/700°C/720°C, yielding efficiencies up to 48%. Lot R&D inputs and

allying with suppliers are required to achieve higher performance.

Moreover,

fuel flexibility is not compromised in Once-Through Boilers. A wide

variety of fuels have already been implemented for once-through boilers.

All types of coal as well as oil and gas have been used.

Conclusion – Thus,

new pulverised coal combustion systems – utilising supercritical and

ultra-supercritical technology – operate at increasingly higher

temperatures and pressures and therefore achieve higher efficiencies

than conventional sub-critical units with significant CO2

reductions. The objective of power plants within toady’s market

boundaries is more than ever to ensure high efficiency (to reduce the

environmental impact as much as possible) while at the same time to

increase their economics in competition to existing alternatives. The

development of an economical and efficient concept needs to look at the

steam turbine all other main components like boiler, flue gas cleaning

equipment and the optimization of the water-steam-cycle as main parts

for the optimization.

Current designs of supercritical plants

have installation costs that are only 2% higher than those of

sub-critical plants. Fuel costs are considerably lower due to the

increased efficiency and operating costs are at the same level as

sub-critical plants. Specific installation cost i.e. the cost per

megawatt (MW) decreases with increased plant size. This plant concept

fulfils the requirement to balance reliable power supply, sustainable

use of existing resources and economic operation.

Today,

supercritical steam turbine cycle is the leading “clean coal”

technology in widespread application. Supercritical steam cycle

technology has been used for decades and is becoming the system of

choice for new commercial coal-fired plants in many countries. Because

of the high performance, efficiency and preservation of much cleaner

environments than sub-critical coal-fired power plants, more than 500

supercritical coal-fired power plants are operating in the developed

countries like US, Europe, Russia and in Japan. Most of the new power

plants coming up now-a-days are of supercritical coal-fired technology.

Recent plant built in Europe and Asia use supercritical boiler-turbine

technology and China has made this standard on all new plant 600MW and

upwards.

In fact, Supercritical steam cycles are not just

applicable to coal-fired plant; oil- and gas-fired plants are also well

proven. Research and development is under way for ultra-supercritical

units operating at even higher efficiencies, potentially up to around

50%. The introduction of ultra-supercritical technology has been driven

over recent years in countries such as Denmark, Germany and Japan, in

order to achieve improved plant efficiencies and reduce fuel costs.

Research is focusing on the development of new steels for boiler tubes

and on high alloy steels that minimise corrosion.

References:

- http://environmentengineering.blogspot.com/2008/02/cleaner-coal-fired-supercritical-power.html

- http://environmentengineering.blogspot.com/2008/02/fludised-bed-combustion-fbc-technology.html

- http://www.powergeneration.siemens.com/NR/rdonlyres/025ABC46-9AA8-451B-88D1-FFE1B42B8966/0/2_Balancing_economics.pdf

- Y. Oka and S. Koshizuka, “Supercritical-pressure, once-through cycle light water cooled reactor concept,” Journal of Nuclear Science and Technology, vol. 38, no. 12, pp. 1081–1089, 2001.

0 komentar:

Posting Komentar